The Mercedes Structural Adhesive is a groundbreaking bonding solution designed to meet the demanding requirements of automotive manufacturing, offering unparalleled strength, durability, and environmental resistance. Guided by STAR (Structured Total Assessment and Repair) protocols, this adhesive ensures optimal performance in auto glass repair, bodywork, and restoration, revolutionizing body shop operations with precise repairs. Its versatility extends beyond autos, demonstrating exceptional holding power and efficiency in construction and manufacturing industries. Case studies highlight its reliability and efficiency when adhering to STAR guidelines, making it a transformative solution for both traditional and innovative uses.

Discover the transformative power of Mercedes structural adhesive, a revolutionary bonding solution setting new industry standards. This article explores its unique properties and unparalleled benefits, providing a deep dive into how it redefines structural integrity. We then navigate The STAR Guidelines, a comprehensive framework ensuring optimal application for various projects. Finally, real-world case studies reveal successful implementations across diverse industries, underscoring the versatility and reliability of Mercedes structural adhesive.

- Understanding Mercedes Structural Adhesive: Properties and Benefits

- The STAR Guidelines: A Comprehensive Framework for Application

- Case Studies: Successful Implementation in Various Industries

Understanding Mercedes Structural Adhesive: Properties and Benefits

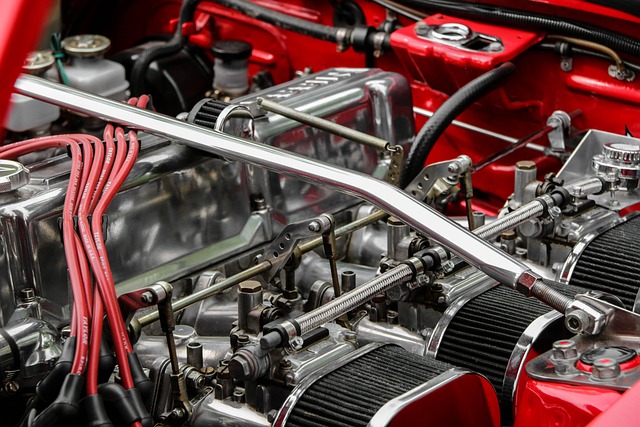

Mercedes Structural Adhesive is a cutting-edge bonding solution designed to meet the stringent requirements of automotive manufacturing. This advanced adhesive offers unparalleled strength and durability, ensuring superior structural integrity in various applications within an auto collision center or auto repair services. Its unique formulation combines exceptional mechanical properties with excellent resistance to environmental factors, making it a game-changer in auto frame repair.

The adhesive’s key benefits include enhanced bonding power, allowing for the efficient assembly of complex automotive components. Its high tensile and shear strength guarantees the structural stability of vehicles, addressing crucial safety concerns. Moreover, Mercedes Structural Adhesive exhibits excellent resistance to temperature variations, moisture, and chemicals, ensuring long-lasting performance in both harsh weather conditions and demanding auto repair environments.

The STAR Guidelines: A Comprehensive Framework for Application

The STAR guidelines provide a comprehensive framework for the application of Mercedes structural adhesives, ensuring optimal performance and durability. STAR stands for Structure, Tolerance, Adhesive type, and Repair methods, offering a systematic approach to adhere to during auto glass repair, auto bodywork, or car restoration processes.

This structured methodology dictates specific parameters for each stage of the bonding process, from preparing the surfaces to be bonded to selecting the right adhesive type for the job. By adhering to STAR guidelines, professionals can guarantee that Mercedes structural adhesives are used correctly, maximizing their strength and longevity.

Case Studies: Successful Implementation in Various Industries

The Mercedes structural adhesive, applied according to STAR (Structured Total Assessment and Repair) guidelines, has proven its mettle in numerous case studies across various industries. In the automotive sector, this advanced adhesive system has revolutionized vehicle body shop operations, offering superior bonding strength for precise auto body repair. From dent removal to complex panel replacement, the Mercedes structural adhesive ensures long-lasting repairs that match the original vehicle’s integrity.

Beyond the automotive realm, its versatility is evident in diverse applications. Construction projects benefit from its robust holding power in adhering to various materials, while manufacturing industries leverage its precision for assembling intricate components. Each case study underscores the reliability and efficiency of the Mercedes structural adhesive when implemented following STAR guidelines, making it a game-changer in both traditional vehicle body repair and innovative industrial applications.

Mercedes structural adhesive, applied according to the STAR guidelines, offers a versatile and robust solution for various industries. By understanding the unique properties and benefits of this adhesive and adhering to the comprehensive framework provided by STAR, professionals can achieve superior bonding results. As demonstrated through successful case studies, this approach ensures durability, strength, and reliability in critical applications, solidifying Mercedes structural adhesive as a game-changer in modern manufacturing and construction practices.