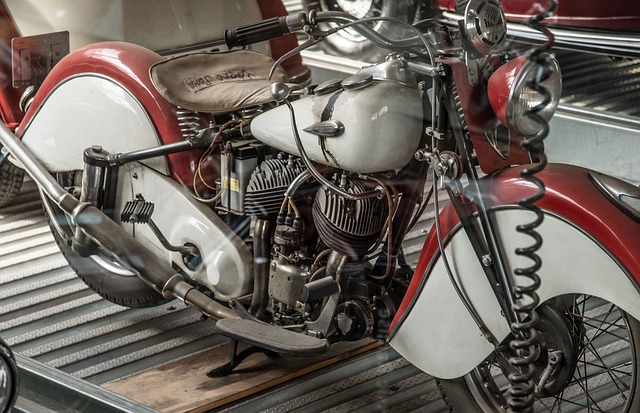

Weld distortion in thin auto panels is a common issue, but the Mercedes Structural Adhesive offers a revolutionary solution. This innovative adhesive mitigates heat effects during welding, preventing unsightly warping or bending and ensuring panels remain flat. By streamlining the repair process, enhancing quality, and providing a durable finish, this advanced adhesive sets a new standard in automotive manufacturing, benefiting professionals and enthusiasts alike across various industries, including Mercedes-Benz restoration.

In the automotive industry, achieving precision and integrity in thin panel assembly is paramount. Weld distortion, a common challenge, can mar the structural integrity and aesthetic appeal of vehicles. This article explores how the revolutionary Mercedes structural adhesive offers a cutting-edge solution to this dilemma. By understanding weld distortion’s impact on thin panels, we delve into the benefits and diverse applications of this advanced Mercedes structural adhesive, showcasing its role in enhancing vehicle manufacturing.

- Understanding Weld Distortion in Thin Panels

- Mercedes Structural Adhesive: A Revolutionary Solution

- Benefits and Applications of This Advanced Adhesive Technology

Understanding Weld Distortion in Thin Panels

Weld distortion in thin panels is a common issue in auto body work and collision repair, often leading to unsightly warping or bending after what should be a straightforward welding process. This phenomenon occurs due to the unique properties of thinner materials; as heat is applied during welding, the metal expands and contracts, causing structural stress that can result in distortion if not managed correctly. In the world of auto body work, maintaining precision and integrity in welds is paramount for both safety and aesthetics.

Mercedes structural adhesive offers a revolutionary solution to combat this challenge. By strategically applying a high-strength adhesive, technicians can mitigate the effects of heat expansion and contraction, ensuring panels remain flat and true after collision center treatments. This innovative approach not only streamlines the repair process but also enhances the overall quality of auto body work, providing customers with a more durable and visually appealing finish.

Mercedes Structural Adhesive: A Revolutionary Solution

Mercedes Structural Adhesive represents a significant leap forward in automotive manufacturing, particularly for thin panel applications. Its innovative formula is designed to address a common challenge in auto bodywork and car restoration—weld distortion. This revolutionary solution offers a durable, reliable alternative to traditional welding methods, ensuring that auto body work remains pristine and structurally sound.

By leveraging cutting-edge technology, the Mercedes structural adhesive provides exceptional bonding strength while minimizing thermal expansion, a primary cause of weld distortion. Its application in delicate panel structures not only enhances structural integrity but also preserves the aesthetic appeal of meticulous car restoration projects. This advanced adhesive is a game-changer for professionals and enthusiasts alike, streamlining auto body work processes and delivering superior results.

Benefits and Applications of This Advanced Adhesive Technology

The Mercedes structural adhesive offers a revolutionary approach to auto maintenance, particularly in the realm of thin panel repair. This advanced technology provides several key benefits, ensuring superior results in vehicle collision repair. Firstly, it minimizes weld distortion, a common issue in traditional repair methods, by creating a robust bond without the potential for warping or deformation. This precision is especially valuable in maintaining the structural integrity and aesthetic appeal of Mercedes-Benz vehicles known for their sleek designs.

Beyond mercedes benz repair, this innovative adhesive has diverse applications across various industries. Its versatility allows for effective use in manufacturing, automotive body shops, and even in construction, where precise bonding is essential. By eliminating the need for complex welding processes or costly material replacements, this technology streamlines auto maintenance procedures, making it a game-changer in vehicle collision repair and beyond.

The implementation of Mercedes structural adhesive represents a significant advancement in mitigating weld distortion within thin panels. By leveraging its unique properties, this revolutionary solution offers enhanced structural integrity and precision in various industries. The benefits of this advanced adhesive technology extend from automotive manufacturing to aerospace, ensuring stronger bonds and improved product quality. Its ability to prevent distortion opens up new possibilities for designing lightweight, yet robust structures, ultimately driving innovation across multiple sectors.